Distributie, Industrie en Logistiek

Integriteit

Voor ons zijn transparantie en loyaliteit echt belangrijk

Kwalitieit

Distributie

Van kleine tot grote winkels, Tecnor werkt al bijna 50 jaar met allerlei detailhandel. Wij begrijpen uw behoefte als geen ander en kunnen u een op maat gemaakte oplossing bieden die aan al uw specificaties voldoet.

Voor balenpersen werken we al bijna 30 jaar met ORWAK! Niet alleen omdat ze een zeer breed assortiment balenpersen hebben (plastiekpersen, kartonpers, enz.) maar vooral omdat ze de beste kwaliteit op de markt hebben. Zoals u hieronder kunt zien, zullen we zeker een pers vinden die past bij uw ruimtebeperking en afvaltype en -volume.

Tot slot begrijpen we het belang van beveiliging en betrouwbaarheid in de detailhandel. Dankzij onze gecertificeerde Techniekers krijgen uw werknemers een opleiding van topkwaliteit over het gebruik van de plastiek of kartonpers en nog belangrijker, u kunt op snelle interventies voor Tecnor vertrouwen in geval van problemen.

Industrie

Logistiek

De logistieke sector heeft installaties nodig die betrouwbaar en snel zijn. Met Tecnor hebt u de garantie dat u toppers van topkwaliteit ontvangt die meer dan 15 jaar werken. Maar u hebt ook de garantie dat gecertificeerde techniekers klaarstaan om u in recordtijd te ondersteunen!

Het belang dat we hechten aan integriteit en veiligheid maakt ons een betrouwbare partner die u altijd zal helpen, ruimte en productiviteit te winnen! Ons team van ingenieurs zal oplossingen op maat ontwikkelen en je gaat jezelf snel afvragen hoe u het eerder deed.

Onze analyse houdt rekening met alle factoren om een oplossing te kunnen bieden die al uw ruimte-, veiligheid-, milieu- en hygiëneproblemen nauwkeurig identificeert.

Onze oplossingen

Image

Naam

Korte omschrijving

Nuttige informatie

Deze versie van TOM is speciaal ontwikkeld voor omgevingen met speciale eisen aan het ontwerp. Om perfect in uw bedrijf te passen, is TOM Junior bedekt met stijlvolle houten planken en wordt de hoogte aanzienlijk verminderd

- Beoordeel verdichting: jusqu’à 7:1

- Afmetingen (b x d x h): 0,620 x 695 x 1295mm

Doordat het afval verdicht is, houdt TOM tot 7 keer meer dan een conventionele afvalbak.

Dankzij de aanraking vrije verwijdering van het afval, houden de gasten hun handen – en TOM zijn neus – schoon!

- Beoordeel verdichting: tot 7:1

- Afmetingen (b x d x h): 0,595 x 722 x 1445mm

De kleine maar sterke en veelzijdige plastiek-, kartonpers model Compact 3110 is ideaal voor zowel karton als plastic.

- Perskracht : 40 kN (4 t)

- Karton: 10 to 30 ton per jaar

- Plastic: 10 to 30 ton per jaar

- Balengewicht: tot 50 kg

- Afmetingen (b x d x h): 0,9 x 0,7 x 2m

Plastiek-, kartonpers Compact 3115 heeft een opening van 80 cm en is handig bij het compacteren van middelgroot hoeveelheden karton en plastic.

Het biedt een dwarsbind mogelijkheid om ook kleine fractie materiaal (b.v. snipperpapier) in een stabiele baal te kunnen compacteren.

- Perskracht : 60 kN (4 t)

- Karton: 10 tot 30 ton per jaar

- Plastic: 10 tot 30 ton per jaar

- Balengewicht: tot 60 kg.

- Afmetingen (b x d x h): 0,94 x 0,8 x 2m

Plastiek-, kartonpers Compact 3120 is perfect voor middelgroot hoeveelheden zowel karton als plastic. Deze nieuwe balenpers in de COMPACT-familie biedt een sterke verdichting ter plaatse, een compacte machine met een indrukwekkende volumevermindering.

- Perskracht : 60 kN (6 t)

- Karton: 10 tot 30 ton per jaar

- Plastic: 10 tot 30 ton per jaar

- Balengewicht: tot 100 kg

- Afmetingen (b x d x h): 1,2 x 0,9 x 2,3m

Plastiek-, kartonpers Compact 3210 is extreem snel met een cyclustijd van slechts 13 seconden! Twee balen passen perfect op één europallet. Het zal ook hardere materialen zoals metalen blikken, metalen dozen, PET-flessen te kunnen compacteren.

- Perskracht : 120 kN (12 t)

- Karton: 30 tot 50 ton per jaar

- Plastic: 30 tot 50 ton per jaar

- Balengewicht: tot 80 kg

- Afmetingen (b x d x h): 1,1 x 0,84 x 2,15m

Het combimodel is een veelzijdige eenheid met twee functies. Met één inzetstuk wordt de Plastiek-, kartonpers snel omgezet in een vatenpers voor 200 liter staalvaten.

- Perskracht: 120 kN (12 t)

- Capaciteit: 30 tot 50 ton per jaar

- Balengewicht: tot 80 kg

- Afmetingen (b x d x h): 1,1 x 0,84 x 2.5m

Compact algemeen afval in 240 l-wielcontainers

Het is een robuuste en betrouwbare machine met een compact en lichtgewicht ontwerp. De Flex 4240 is veilig en gemakkelijk te gebruiken!

- Perskracht: 15 kN (1.5 t)

- Capaciteit: 10 tot 30 ton per jaar

- Afmetingen (b x d x h): 1,4 x 0,9 x 2,2m

Model Flex 5010-E is een kleine maar sterke balenpers die weinig ruimte in beslag neemt.

Het invoeren van materiaal in deze balenpers met topbelasting is snel en gemakkelijk.

- Perskracht: 30 kN (3 t)

- Karton: 10 tot 30 ton per jaar

- Plastic: 10 tot 50 ton per jaar

- Balengewicht: tot 60 kg

- Afmetingen (b x d x h): 0,91 x 1,1 x 2,14m

Model Flex 5031 is een kleine, sterke en veelzijdige balenpers. Het kan standaardbalen maken, afval in zakken compacteren en / of worden gebruikt om balen in plastic zakken te omsluiten!

- Perskracht: 30 kN (3 t)

- Plastic: 10 tot30 ton per jaar

- Karton: 10 tot 30 ton per jaar

- Balengewicht: tot 40 kg

- Afmetingen (b x d x h): 0,8 x 1,13m x 1,94/2,7m

Deze veelzijdige, stevige toch eenvoudig en betrouwbaar te gebruiken eenheid gaat nog steeds sterk en biedt hygiënische verdichting van gemengd afval.

- Perskracht: 30 kN (3 t)

- Capaciteit: 10 tot 30 tonper jaar

- Afmetingen (b x d x h): 0,8 x 1 x 1,91/1,44m

Model Multi 5070 biedt effectieve comprimeren met meerdere kamers in weinig ruimte! De Multi 5070 met multikamer is een ruimtebesparende plastiek en kartonpers voor al uw afval dat direct bij de bron wordt gesorteerd.

- Perskracht: 30 kN (3 t)

- Karton: 30 tot 50 ton per jaar

- Plastic: 30 tot 90 ton per jaar

- Balengewicht: tot 50 kg

- Afmetingen (b x d x h): 1,74 x 0,9 x 2,16m

Deze heavy-duty evolutie van model Multi 5070 is robuust en veelzijdig. Het is voorbereid op het dwarsbinden van de balen en verwerkt harde soorten materiaal zoals PET-flessen, plastic kannen, voedsel- en verfblikken.

- Perskracht: 100 kN (10 t)

- Karton: 30 tot 70 ton per jaar

- Plastic: 30 tot 110 ton per jaar

- Balengewicht: tot 80 kg

- Afmetingen (b x d x h): 2,22 x 1,74 x 0,9m

Model Multi 9020S-model is de hoge capaciteit model in de Multi-productfamilie. Het kan eenvoudig worden uitgebreid met extra perskamers om een mini-recyclingstation te vormen. De Multi 9020 met multikamer is een ruimtebesparende plastiek en kartonpers voor al uw afval dat direct bij de bron wordt gesorteerd.

Deze pers komt met een veiligheidsrem, die bijdraagt aan een nog veiligere werkomgeving!

- Perskracht : 200 kN (20 t)

- Karton: 70 tot 130+ ton per jaar

- Plastic: 70 tot 130+ ton per jaar

- Balengewicht: tot 200 kg

- Afmetingen (b x d x h): 2,48 x 1,14 x 2,42m

De plastiek en kartonpers Power 3320 is geen 2 m hoog in operationele stand en kan toch kartonbalen maken van 200kg. Het wordt geleverd met een normale pendeldeur en is perfect voor locaties met een lagere plafondhoogte.

- Perskracht: 185 kN (18.5 t)

- Capaciteit: 50 tot 70 ton per jaar

- Balengewicht: tot 200 kg

- Afmetingen (b x d x h): 1,8 x 1 x 2 m

De plastiek en kartonpers Power 3325 is een uitstekende keuze voor zowel karton als plastic. Gelijk aan model 3420 echter zonder de automatische schuifdeur.

- Perskracht: 260 kN (26 t)

- Capaciteit: 50 tot 90 ton per jaar

- Balengewicht: tot 400 kg

- Afmetingen (b x d x h): 1,8 x 1 x 2,4m

Model Power 3420 is een veelzijdige balenpers voor grote hoeveelheden karton en plastic. Het is erg snel met een cyclustijd van slechts 24 seconden en is uitgerust met een automatische schuifdeur die in minder dan 2 seconden omhoog gaat.

- Perskracht : 260 kN (26 t)

- Karton: 50 tot 90 ton per jaar

- Plastic: 50 tot 130 ton per jaar

- Balengewicht: tot 400 kg

- Afmetingen (b x d x h): 1,8 x 1 x 2,4m

Dit kartonpers is het echte zware model voor zeer grote volumes kartonnen dozen en ook sterk kartonmateriaal. Het biedt effectieve verdichting in dichte balen met ideale afmetingen voor een optimale transportlogistiek.

- Perskracht : 520 kN (52 t)

- Karton: 70 tot 130 ton per jaar

- Balengewicht: tot 450 kg

- Afmetingen (b x d x h): 1,9 x 1 x 2,5m

Kartonpers Model Power 3820 heeft een extra royale laadpoort voor grote dozen tot 1500 mm breed. Het is erg snel met een cyclustijd van slechts 24 seconden en is uitgerust met een automatische schuifdeur die in minder dan 2 seconden omhoog gaat.

- Perskracht: 260 kN (26 t)

- Karton: 70 à 130 ton per jaar

- Balengewicht: tot 500 kg

- Afmetingen (b x d x h): 2,1 x 1 x 2,6m

Volledig geautomatiseerde horizontale balenpersen voldoen snel het afvalmateriaal op een kosteneffectieve manier om u te helpen de interne logistiek te verbeteren. De continue balenwerking past perfect met ploegwerk.

- Automatische start met fotocellen

- Automatische bediening

- Automatische baalkoppelingen,

Volledig geautomatiseerde horizontale balenpersen voldoen snel het afvalmateriaal op een kosteneffectieve manier om u te helpen de interne logistiek te verbeteren. De continue balenwerking past perfect met ploegwerk.

- Automatische start met fotocellen

- Automatische bediening

- Automatische baalkoppelingen,

Afbeelding

Naam

Korte beschrijving

Nuttige informatie

“Classic” stationaire persen met centrale en longitudinale Hydraulische aansluiting zullen bij voorkeur worden gebruikt voor kleinschalige materialen.

- Druk: 300 kN (30 t)

- Vermogen kW: 7,5

- Cyclusduur: 32 seconden

- Vulopening (m): 1,4 x 1,5

- Lengte: 4,0 m

Husmann Short stationaire persen met cross hydraulische Jacks bieden een zeer grote vulopening met een beperkte totale lengte en zijn daarom ideaal voor karton.

- Druk: 340 kN (34 t)

- Vermogen kW: 5,5

- Cyclusduur: 43 seconden

- Vulopening (m): 1,5 x 1,9

- Lengte: 2,2 m

Vergelijkbaar met de ST-SEL stationaire pers, is dit model compacter maar behoudt het een indrukwekkende vulopening.

- Druk: 340 kN (34 t)

- Vermogen kW: 5,5

- Cyclusduur: 43 seconden

- Vulopening (m, L x l): 1,5 x 1,6

- Lengte: 2,2 m

De HSP schroef stationaire Compactor maakt een zeer sterke vulling van de verdichting doos, het is geïndiceerd voor grote stukjes karton. Het is 100% elektrische apparatuur, aangeboden met of zonder een oven apparaat.

- Vermogen kW: 11-15

- Vulopening (m, L x l): 1,2 x 1,5 of 1,5 x 1,5

- Lengte: 2,2 m

Hydraulische kiplader voor 2-of 4-wiel containers met standaardcontainers, afhankelijk van verschillende containers. Verkrijgbaar in verschillende uitvoeringen/configuraties: stationair, mobiel of geïntegreerd met verdichtings apparatuur.

Afbeelding

Naam

Korte beschrijving

Nuttige informatie

De Husmann gigant 1750 Compactor roller is ideaal voor het reduceren van het volume van volumineus afval zoals houten pallets en kratten, oude meubelen, metalen dozen en andere lichtmetalen of volumineuze afval sets.

- Totaal gewicht: 3.600 kg

- Rol massa: 1.350 kg

- Breedte rol: 1.750 mm

De gigant GT-M 1750 is de mobiele, op zichzelf staande versie van de Husmann Gignat 1750 Compactor roller. Het haalt zijn kracht uit een diesel groep voor zowel verdichting als reizen.

- Totaal gewicht: 8, 100kg

- Roller massa: 2.000 kg

- Breedte rol: 1.75 m

Afbeelding

Naam

Korte beschrijving

Nuttige informatie

Husmann verdichtings dozen, ook wel bekend als “Monoblocks” zijn zeer duurzaam, vereisen weinig onderhoud, zijn betrouwbaar met een lange levensduur.

De SPB SEN/SEL serie is ontwikkeld voor droge stof.

- Vermogen: 5.5 kW

- Vermogen: 380/400V, 50Hz

- Compressiekracht: 310kN

- Vermogen hoogte: 1,44 m

- Capaciteit: 16 tot 24 M3

- Lengte: 5,6 tot 7,2 m/6 tot 7,6 m

Husmann verdichtings dozen, ook wel bekend als “Monoblocks” zijn zeer duurzaam, vereisen weinig onderhoud, zijn betrouwbaar met een lange levensduur.

- Vermogen: 5.5 kW

- Vermogen: 380/400V, 50Hz

- Compressiekracht: 310kN

- Vermogen hoogte: 1,67 m

- Capaciteit: 16 tot 26 M3

- Lengte: 5,2 tot 7,3 m

Hspc-type draagbare hspc-verdichters kunnen worden gebruikt voor verschillende soorten materialen zoals karton, plasticfolies, houten kisten en algemeen afval.

- Vermogen: 11kW

- Vermogen: 3 x 380/400V

- Vermogen hoogte: 1,67 m

- Capaciteit: 18 tot 22 M3

- Lengte: 6,2 tot 7m

Afbeelding

Naam

Korte beschrijving

Nuttige informatie

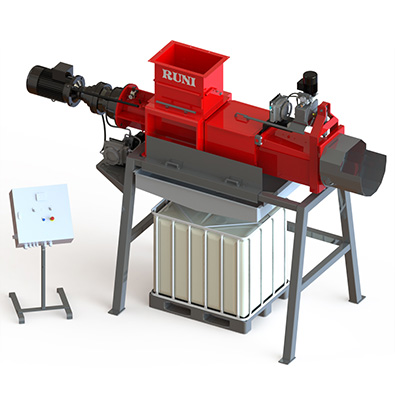

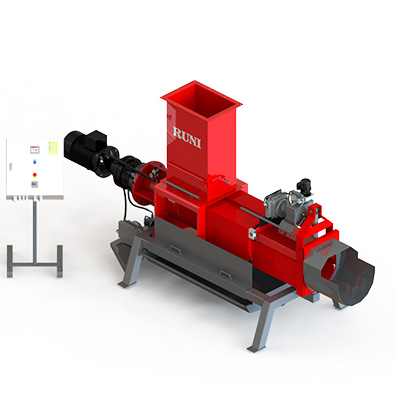

De Runi SK120 is de ideale oplossing voor milieubewuste supermarkten, huishoudelijke apparaten dealers, elektronica retailers en visverkopers en zeevruchten distributeurs die op zoek zijn naar controle afvalkosten.

- Opening laden: 0,3 x 0,75 m

- Blok dichtheid: 300 kg/m3

- Vermogen: 3 x 400/380V, 50Hz

- Capaciteit per uur: 18 kg/uur

- Afmetingen (l x p x h): 2,80 x 0,50 x 1.75 m

Deze Compactor heeft een 4 kW motor en een ingebouwde slijpmachine. Het is verkrijgbaar in twee uitvoeringen: met continue handmatige of automatische afstelling (dankzij een hydraulische groep) voor een regelmatige koelsnelheid.

- Opening laden: 0,4 x 0,75 m

- Blok dichtheid: 300 kg/m3

- Vermogen: 3 x 400/380V, 50Hz

- Capaciteit per uur: 45 kg/uur

- Afmetingen (l x p x h): 2,8 x 0,5 x 1,63 m

De SK240 Compactor is uitgerust met een continu elektrohydraulisch regelsysteem en wordt geconfigureerd om te voldoen aan de operationele eisen.

- Opening laden: 0,4 x 0,8 m

- Blok dichtheid: 270 kg/m3

- Vermogen: 3 x 400/380V, 50Hz

- Capaciteit per uur: 75 kg/uur

- Afmetingen (l x p x h): 4,3 x 1,2 x 2.2 m

Krachtigere, grotere verwerkingscapaciteit. Veel configuraties voor verschillende materialen, een normale pre-Shredder of “Heavy Duty”: de SK 370 schroef Compactor is een robuuste apparatuur ontworpen om een verscheidenheid aan materialen te verwerken en succesvol waar anderen moeten stoppen.

- Opening laden: 0,5 x 1/1,2 m

- Blok dichtheid: 300 kg/m3

- Vermogen: 3 x 400/380V, 50Hz

- Capaciteit per uur: 200 kg/uur

- Afmetingen (l x p x h): 5,4 x 1,35 x 2.3 m

Het vloeistof scheidingssysteem barst en comprimeert de flessen en blikjes continu terwijl de vloeistoffase afzonderlijk wordt teruggeboekt. Een capaciteit van maximaal 20.000 PET-flessen van 0,5 liter per uur of 8.000 PET-flessen van 1,5 liter per uur.

- Dichtheid: 250-600 kg/m3

- Vermogen: 3 x 400/380V, 50Hz

- Capaciteit per uur: 15.000 l/uur

- Afmetingen (l x p x h): 5,9 x 1,35 x 1.93 m

Contacteer ons

Français

Français